رسالة على الانترنت

رسالة على الانترنت

المزيد من المعلومات

المزيد من المعلومات

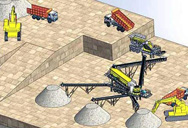

2021.6.24 crushing process. We are the world’s leading supplier of both unit machines and complete aggregates processing systems. Comprehensive process solutions Your system may involve a whole series of proc-esses, such as crushing and screening,

Read More

2022.10.4 7 Citations. Explore all metrics. Abstract. The worldwide mining industry consumes a vast amount of energy in reduction of fragment size from mining to mineral

Read More

Crushing. Some ores occur in nature as mixtures of discrete mineral particles, such as gold in gravel beds and streams and diamonds in mines. These mixtures require little or no crushing, since the valuables are recoverable

Read More

2017.3.4 There are two kinds of. equipments used for crushing work s. one is by using crushers and other one is by using impacto rs. This

Read More

2020.11.8 Mineral Processing: Crusher and Crushing. November 2020. DOI: 10.13140/RG.2.2.13982.36167. Conference: Tanta University. Authors: Hassan Z. Harraz. Tanta University. Abstract. Mineral...

Read More

2016.1.1 Mining energy consumption contributes to mining operational costs and occurs at all stages of the ore recovery process: blasting, excavation, crushing, transport

Read More

1996.3.1 The reduction of circulating load from 52.345 to 26.312% influences on that, too. All these have positive effect on damage prevention of main mechanical

Read More

2019.12.10 This thesis focuses on developing models of crushers and equipment used in the mining industry. Specifically, the focus is on a branch of modeling called time

Read More

Abstract. The size to which particles are reduced is governed by three criteria: (i) the required product size if simple sizing only is desired; (ii) the particle size of the mineral

Read More

2019.12.10 Cone crushers are mostly used for the large scale crushing in the mining industry. It has the advantage of reliable construction, high productivity, easy adjustment and lower operational costs. The spring

Read More

August 13, 2018. Contract crushing and mining specialist African Mining and Crushing has in less than 10 years established itself as a true expert in the field and strives to consistently deliver the lowest sustainable cost per ton crushing solutions – across the African continent. This can be attributed to the company’s dedicated employees ...

Read More

2024.3.12 The energy problem. One of the most pressing issues in crushing and grinding is the sheer amount of energy these processes use. They account for around 56% of the mining sector’s total energy usage – which adds up to 3% of the entire planet’s generated electric power usage. Given that one of the major factors driving the push for

Read More

2019.3.5 African Mining Crushing’s innovative approach delivers quick results. By Laura Cornish. March 5, 2019. AMC delivers every project according to its lowest, sustainable, cost per tonne core philosophy. Securing investors and delivering a return on their investment has become one of the key challenges facing the junior mining sector,

Read More

2023.12.5 Selective Crushing: VSI crushers allow for selective crushing of material, which means that certain types of material can be processed more efficiently than others. Applications: Vertical Shaft Impactors are commonly used in the production of high-quality aggregates, particularly for the construction and mining industries.

Read More

Mining Ore Crushing Equipment Expert. Henan Province, China Zhengzhou West Industrial Zone,451200 +86 1830843555 sales@moledive Mon - Fri: 9:00 - 17:30 ... This crusher finds common applications in the mining, coal processing, and power generation industries, facilitating the processing, transportation, and utilization of coal. ...

Read More

2022.10.4 The worldwide mining industry consumes a vast amount of energy in reduction of fragment size from mining to mineral processing with an extremely low-energy efficiency, particularly in ore crushing and grinding. Regarding such a situation, this article describes the effects of rock fragmentation by blasting on the energy consumption ...

Read More

2020.3.1 Grain crushing in geoscience materials–Key issues on crushing response, measurement and modeling: Review and preface. ... crushing is commonly encountered in deep foundation engineering, high rockfill dam engineering, railway engineering, mining engineering, coastal engineering, petroleum engineering, and other geoscience

Read More

Crushing is the process of size reduction of ore. Size reduction process begins with usage of explosives at the area for production of ore. In later stages, the size reduction process performed with crushers before grinding in mills is called "crushing". Although there is no limit set, the downsizing process over 3 mm is considered as "crushing ...

Read More

2021.3.25 Similar to Sizers, Roll Crushers can be used for the primary crushing of soft to medium hard material that can be slightly abrasive, dry, or wet and sticky. They are typically used in heavy mining applications and have a typical ratio of reduction of 4:1. Primary Roll Crushers are available in several designs: Single Roll; Double Roll; Triple Roll

Read More

2021.6.10 These are typically the single biggest user of electricity at a mine site, accounting for anywhere from 25% to more than 50% of consumption. 1,2 Indeed, comminution in the mining industry may account for 1% to 3% of total final global energy consumption;1,2 in countries where mining accounts for a significant proportion of

Read More

2023.10.4 Mining balls, in various forms such as grinding balls, steel grinding balls, forged steel grinding balls, and rolled grinding balls, are indispensable components in the mining industry.These durable and precisely crafted spheres play a pivotal role in crushing and grinding raw materials, contributing to efficient material processing and resource

Read More

2019.3.20 Capex costs can have up to a 42% effect on the cost per tonne when measured accurately,” Hughes reveals. In summary, the results of the AMC business model for the mine owner and the investment community are: Correctly de-risking mining projects; Validating assumptions through an operational model before large investments happen;

Read More

March 20, 2019. Contract crushing and mining specialist African Mining and Crushing has in less than 10 years established itself as a true expert in the field and strives to consistently deliver the lowest sustainable cost per ton crushing solutions – across the African continent. This can be attributed to the company’s dedicated employees ...

Read More

2023.2.28 It is also used in the mining industry for processing ores and minerals. Differences between Primary Crushing and Other Comminution Processes. Primary crushing is different from other comminution processes, such as grinding, in that it breaks down the material using mechanical force, rather than by using friction or impact.

Read More

mineral processing, art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or gangue. It is the first process that most ores undergo after mining in order to provide a more concentrated material for the procedures of extractive metallurgy. The primary operations are comminution and ...

Read More

Sandvik Rock Processing Solutions. Business area Sandvik Rock Processing Solutions is a leading supplier of equipment, tools, parts, service and solutions for processing rock and minerals in the mining and infrastructure industries. Applications include crushing, screening, breaking and demolition. The focus lies on bringing value to customers ...

Read More

2024.4.6 DOVE Equipment Machinery manufacturing facilities are located about 30 minutes drive from the company Head office in Bangkok, which includes 8 factories and showroom. DOVE Equipment and Machinery with over 50 years manufacturing expertise, and the largest range of mining and minerals processing technologies is the recipient of

Read More

2020.4.20 Crushing is the process of reducing the size of materials so that they can be further processed. In addition to being used in the chemical, coal industry, constrction area and so on area, industrial crushing equipment can be very useful in those variety of businesses. Also, crushin processing is widely used in waste and recycling, mining, food ...

Read More

Our purpose built Modular 600tph Coal plant producing Eskom spec for a client in Mpumalanga area. Call us for your contracting or plant solutions. African Mining and Crushing SA (Pty) Ltd 2,944 followers on LinkedIn. We're an innovative and dynamic company within the Construction and Mining Industries,that is quickly becoming a market

Read More

2019.8.2 Having begun on site in January 2014, AMC designed and built a new 1 200 tph crushing and screening plant in conjunction with the mine in 2017 and was awarded a three-year contract in 2018 to operate the plant as well. “We are exceeding our operating parameters on the plant and continue to deliver a very successful operation,” Schweitzer ...

Read More

2021.4.16 In mining operations, the comminution process reduces the mined solid materials through crushing, grinding and other means. SAG and Ball mills are one of the most critical pieces of equipment for the process. Mining operators need to optimize grinding mill performance, and reliability to ensure tight shutoff.

Read More

2023.7.22 Ore medium crushing is a process of crushing ore blocks with a feeding particle size of 125–400 mm to 50–100 mm. The maximum crushing ratio of medium crushing is about four. The force in the process of ore crushing is mainly crushing and impacting. The main equipment suitable for medium crushing operations is a jaw crusher,

Read More

2016.1.1 Mining energy consumption contributes to mining operational costs and occurs at all stages of the ore recovery process: blasting, excavation, crushing, transport and grinding (comminution). For example, the copper mining industry is expected to consume 41.1 terawatt-hours (TWh) in 2025, an increase of 95.5 percent from 2013 [11].

Read More

2022.9.15 The crushing process can be accomplished in one or more stages - primary, secondary, tertiary and quaternary - and include a variety of crusher types. Selecting the right crusher for an application begins with a consideration of all the components of the crushing process, including the factors that affect the crushing

Read More

2018.12.12 The production cycle of open-cast coal mines generally includes drilling, blasting, loading, hauling and coal preparation activities. Individual optimization of these activities does not mean that the whole system is optimized. This paper proposes a cost model considering all activities in mining cycle and system-wide approach to minimize

Read More

Sampling is a vital part of the crushing process, to ensure that you know the size distribution of the feed. It’s crucial that sampling is done regularly, especially when there are changes in blasting, mining or any other upstream processes. Feed moving towards a crusher in the Sandvik-designed Deer Park quarry in Melbourne, Australia.

Read More

2016.2.24 stock and provide spare parts close to the mining operation. Good geotechnical information is essential to crushing plant siting and design. Installing a primary crushing plant on solid rock reduces the cost of concrete and structural steel. Life of Mine/Expansion Plans The life of the mine is a key element in the design of any crushing

Read More

2024.2.23 For example, in mining, the ore might need more crushing. This is so it can be small enough for grinding. Or, so we can take out important metals right away. Getting a good start on primary crushing is critical for all that follows. It can help you save money while also improving the finished product. People in charge can really affect the ...

Read More

2021.9.30 The screening process serves to separate particles of different sizes and is ideal to ensure that the product reaches the market in the right size, shape and quality. In aggregate production, the screening process is a key part of the production process and is carried out on a large scale. Therefore, it is necessary to make sure that the ...

Read More

المزيد من المعلومات

المزيد من المعلومات

حقوق حقوق التأليف والنشر: رقم التدوين Development Buide 10200540 -22. خط الخدمة: 0371-86549132. E-mail:[email protected] العنوان: الرقم البريدي رقم 169 Second Avenue Avenue New Avenue: Chengzhou الصين: إحصاءات الموقع الشبكي 450001.